Healthcare

The Issue

Hospitals and long-term care facilities can be breeding grounds for dangerous microbes. In the past few years, antimicrobial-resistant strains of bacteria and viruses have become prevalent in healthcare spaces.

Healthcare Associated Infections (HAIs) can be acquired by patients during their treatment in healthcare centers. While completely preventable, these infections lead to unnecessary suffering and severe decreases in patient satisfaction and quality of treatment. Hospitals and care centers experiencing increased levels of Healthcare-Associated Infections create a dangerous patient environment and can face exorbitant costs and legal action.

The Solution

-

Hospitals/Clinics

Our products are EPA registered for hospital disinfection. SMT's chlorine dioxide eliminates pathogens at point-of-use. -

Long-Term Care Centers

Our ultra-pure chlorine dioxide eradicates dangerous microbes to create an ideal patient environment for a healthy recovery. Selectrocide® has successfully destroyed the following human health pathogens in testing performed by accredited laboratories:- Coronavirus

- Methicillin-resistant Staphylococcus aureus (MRSA)

- Pseudomonas aeruginosa

- Vancomycin-resistant Enterococcus faecalis (VRE)

- Human Immunodeficiency Virus type 1 (HIV-1)

- Poliovirus-1

- Rotavirus

- Norovirus (feline calicivirus surrogate)

Healthcare Applications Video:

Recommended Products

-

Selectrocide® 1G

Regular price $39.95Regular priceUnit price / per -

Selectrocide® 5G

Regular price $79.95Regular priceUnit price / per -

Selectrocide® 12G (8 Pack)

Regular price $1,359.92Regular priceUnit price / per -

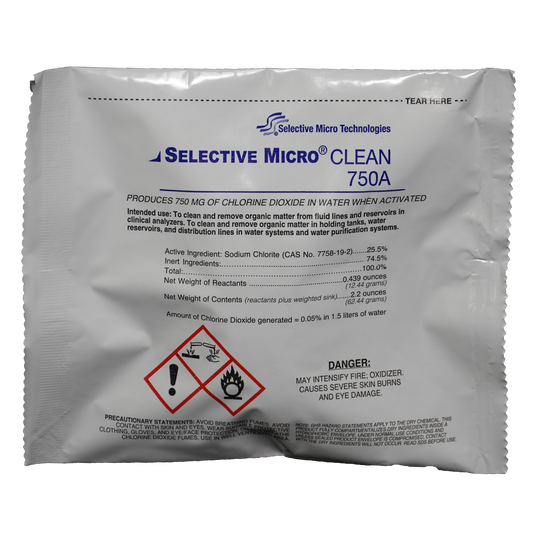

Selective Micro Clean 750A

Regular price $39.99Regular priceUnit price / per -

Selectrocide® 12G Kit

Regular price $799.99Regular priceUnit price / per -

Selectrocide® 5G Kit

Regular price $599.99Regular priceUnit price / per

Related Case Study

Keep the surface and the air clean in the healthcare environment

Healthcare professionals understand the significance of proper disinfection techniques. Pure chlorine dioxide exists as a gas in its natural state and is highly soluble in water. Also it presents a non-corrosive, easy-to-use, and more effective alternative to chlorine bleach. Pure chlorine dioxide is able to kill more pathogens at a disinfection concentration that is fractional when compared to chlorine bleach. This provides a safer, non-corrosive alternative for surface disinfection in health-care facilities.

The Issue

Laboratories and hospitals utilize high-tech and precise equipment to analyze and diagnose patients. These high-throughput machines are very precise and require consistent care to maintain their accuracy. One element of care is consistent decontamination to prevent false readings caused by pathogens such as bacteria or viruses.

With some products, this decontamination sequence can cause a lot of downtime, precluding clinical analyzers and other machinery from running valuable tests. This will delay results and increase cost of testing.

The Solution

-

Laboratory

Our EPA registered disinfectants can be used to disinfect any hard, non-porous surface in your lab, such as:- Bench tops or other work areas

- Biological hoods or safety cabinets

- Water reservoirs and systems

Recommended products:

Selectrocide® 5G -

Diagnostics

Our pure chlorine dioxide products can be used in diagnostic analyzers to:- Decontaminate membranes

- Remove organic material from water resorvoirs

- Decontaminate fluidic lines

Recommended products:

Micro Clean 750A

Related Case Study

Field Trial: Decontamination of USP water purification systems and distribution loop

USP Water System Distribution Loop

The water system and distribution loop included two 125-gallon water storage tanks plumbed in parallel. The tanks store RO/DI water that feeds the distribution loop. A system diagram is included in Figure 1. The storage tanks were full of water at the beginning of the decontamination process. Prior to starting the procedure, the DI tanks were removed from the system. Chlorine dioxide was generated directly in the storage tanks. During the generation period, water was recirculated through the loop, returning to the tanks. No make-up water from the RO unit was added to the tanks during the generation and recirculation period, and power to the in-line UV lights was disconnected.

Get In Touch

Let's Talk

Ask us about your application and delivery needs